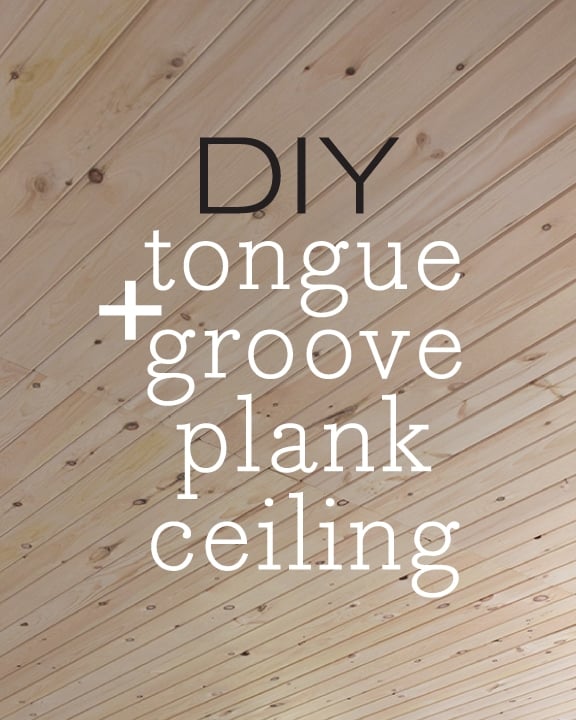

Today I’m sharing how to install real tongue and groove planks on your ceiling. This weekend DIY will transform any room, and it’s easier than you think!

Jump to:

Materials

- Tongue and groove boards (mine were 3/4″ thick, 5 1/8″ wide, and 8′ long. I like pine because it’s lightweight and easy to work with. Make sure to get extra for cut and damaged boards).

- Liquid Nails

Tools

- Finish nailer + nails

- Miter Saw

- Jigsaw or table saw (we ended up using both)

You can use a wide variety of materials (wood, mdf, composite) or even 8′ sheets (such as beadboard) to achieve a similar look, depending on your preference. I found this cost-effective unfinished tongue and groove pine at Lumber Liquidators:

Tongue and groove is double sided so you can use one for hardwood floors, and the other is meant for paneling walls and ceilings. Here’s the flat side for floor installs:

And here’s the tongue and groove side (this is the side that will be exposed):

How to install tongue and groove boards on a ceiling

Step 1: Plan your layout

Our ceiling is just under 24 feet long at the widest point:

Since my boards were 8 feet long, I decided to use three even rows and hide the seams with a beam running perpendicular (three beams total). If you aren’t going to add beams, you’ll want to cut your boards at various lengths to stagger the seams. I prefer the seams to blend in as much as possible, so I would caulk and sand afterwards (I’ll be taking this approach with the back wall since it is slightly wider than 8 feet).

Step 2: Mark joist lines on the ceiling

Before you start, you’ll need to mark your joists. We bought a chalk line and had them all marked for drilling our light and speaker holes:

It’s a little difficult to see, but there are light blue lines running throughout. Our ceiling was a little weird because the beams ran horizontal in the front and perpendicular in the back. This meant that most of the boards up front wouldn’t be nailed into a stud, which is where liquid nails comes in…

Step 3: Attach planks to ceiling

For our first board, we decided to start in the back corner of the room.

We lined up the groove/flat side to the edge of the wall so the tongue was exposed, and shot a couple nails through on each end and along the edges. Luckily, it didn’t fall!

To allow room for expansion, you’ll want to leave around a half inch of space between the walls. Our wood didn’t sit indoors long enough to acclimate to the environment so this was especially important.

The next board locked in place quite easily. We shot a few more nails into the edges and several along the tongue. This part is important—to avoid having to fill a million tiny nail holes, you want to angle the gun inward at a 45 degree angle on the tongue:

The blue chalk line represents a joist, which you’ll want to make sure to hit (unless there aren’t any that cross your board).

Since the tongue will be covered by the groove of the next board, this will ensure all of your nails are hidden. It takes some time to get the hang of it, but after about 100 boards I finally started to look like a pro!

Moving along…

Step 4: Working around lights/speakers

Back to those holes we cut. Many of you won’t do it this way because you’ll already have lights in your ceiling, but we had none and wanted to add recessed lights and speakers, so first we had to plan and cut out all of the locations.

When we came across a board that covered the holes, we stapled a tag to the top of it (labeled as “Speaker” or “Light”. Then we installed the board as normal:

The reason we couldn’t just drill through the planks and drywall at the same time is because the tabs on the inside of the lights and speakers are made to grip onto 1/2″ thick drywall only. The planks and drywall together are too thick, so we had to cut the drywall away so the tabs would attach to just the planks. Make sense? I’ll explain this more in Step 6 (with photos).

After you get the first board up, it’s pretty much just rinse and repeat.

Once we got to the back of the room, the joists started running the other way so we were able to nail into them. We used two nails on the edges and one where the board met each stud (on the tongue).

Making progress, five inches at a time…

After a couple hours, we made it to the end of the first row!

Somehow, it lined up almost exactly perfect to the back wall so we didn’t have to rip down any boards. We had to make a tiny notch where it met the pantry wall using a jigsaw, but we got lucky.

For the second row, we just made sure the edges were lined up with the first row.

Warped and stubborn boards

Sometimes the board slid right in effortlessly and lined up perfectly on both sides. Other times it was a little warped and needed some persuasion. To avoid damaging the groove, we used a scrap piece to attach to the end and hammer it in. Usually that was all it took to nudge right in.

For the most stubborn boards, a pry bar was used to wedge it in place while we nailed.

The great thing about this wood is that it’s soft which means very forgiving. I can’t tell you how many nails we didn’t angle in correctly (aka straight up into the ceiling, in the way of the next board), but we were able to tap the board right in with a hammer. It also helped that the nails were thin and easily bendable, so if we didn’t line it up just right the first time, we could push it into place and nail it again.

Step 5: Rip down the last row

Eventually we reached the back wall. As you probably know, most walls and ceilings aren’t built completely level, so by the time you get to the back of the wall, you’ll be lucky if everything is aligned perfectly.

We kept this in mind and started measuring the distance to the back wall on each side about halfway through so we could make small adjustments on either side to stay parallel. Even still, we ended up with a 1″ gap on one end, and a 2″ gap on the other end.

For our last piece, we measured and marked our gap on a board and cut it out with a jigsaw:

It didn’t matter at all if the line was cut straight since it would be covered with a piece of trim along the edge.

Two rows down, one to go!

Same process here, except we had to trim down about 30″ off the length of the first section since the wall was shorter.

Then we came across an obstacle—we’d have to notch out a piece to wrap around this wall. It was simple, really—we just measured where the wall came out, traced it onto our board, and cut (again with the jigsaw—though you could just as easily use a table saw):

And again, since this will all be hidden, nothing has to be exact. It was pretty dang close anyway though:

As we were nearing the home stretch, I noticed the ceiling was off…

…like, way off. Not straight at all.

It became an issue when I saw how bad the ends of the boards were bowed down.

The main reason this is an issue is because I plan to install a beam there, and it won’t sit flush up against the ceiling if it’s wavy.

We grabbed some long screws and Brad tried to pull them back up as tight as he could.

|

| That gap will be hidden by the beam, don’t worry! |

We weren’t able to get them completely level, but the screws did help a lot. I plan to add a small piece of trim after the beams are up to hide any gaps.

After clearing that last hurdle, we made it to the very end—and this time we got the spacing right! We ripped down a 2.5″ piece using a table saw and nailed it into place for the final piece.

And then we were able to step back and admire our hard work…

Step 6: Install the lights

We had marked each light and speaker location with green tags when installing the boards. In the attic, the tags were identified, and a hole drilled down through the drywall opening. Then the wire was fed through.

With the location marked, an arbor was used to drill a hole for the light.

Test fit—success!

The speaker holes were much larger, so those were cut out by hand using a jigsaw (first I traced the opening onto the ceiling using the template that came with the speakers):

There’s a lip that covers the opening, so perfectly smooth circles aren’t necessary.

Worked again!

In total, we have 13 recessed lights, 3 pendant lights, and 4 speakers.

Step 7: Prime and paint

If your planks are real wood (especially with knots) it’s imperative to use a good oil-based primer to stop the tannins from bleeding through over time.

We also had a few large holes/knots that I filled in with Presto Patch:

We painted the ceiling with two coats of Kelly Moore Swiss Coffee in satin:

What a difference!

Here’s the finished result after installing simple DIY wood beams:

Looks like a million bucks, right? Fortunately, you don’t need to be a professional to try this at home!

Installation Tips

- If you can’t nail into your ceiling joists, attach 1×2′ battens to the ceiling to nail into

- If you aren’t hiding the seams under beams, stagger the boards for a random look

- Leave 1/2” of space between the planks and walls to allow for expansion

- Nail onto the tongue of the board where it won’t be visible

- Nail the boards in at an angle for added strength

- Use a pry bar or scrap piece of wood to hammer stubborn boards into place

Helpful Resources

- Here’s a video (old school but useful)

- This tutorial from Sawdust Girl

- Family Handyman tutorial

Keven says

Any tips on painting? Do you think it would have been better to paint prior to application?

jennasuedesign says

You have to paint after — just use a really, really good primer!

Ray says

Nice job, but I’m wondering why you did not go with offsetting the planks rather then the straight lines where the ends of the planks meet? In my opinion, offsetting the planks look much better.

Ray

jennasuedesign says

The seams are covered with beams 🙂

Anonymous says

I agree about staggering the boards. One quick fix to that you don't need to take anything down is to make faux ceiling beams and place them on the joints. That would give the room a rustic look.

Anonymous says

You guys did a good job. When we did ours we staggered the boards so the ends didn't make a straight line. The same way we did our hardwood floors. it makes it look blended rather than 2 runs of boards. Easy to do, you take your excess from you first run and start you next with the cut-off.

HAROLD ROBERT says

Wow…Great Job…

Kitchen Cabinet Doors Miami Florida

Mel-A- Palooza says

I'm anxious to see the progress on that kitchen! Everything is looking great so far, and I'm super jealous of that awesome theater room!

Cindy @Made2Style says

You guys have some dedication! I have to say I do love how the raw wood looks but I'm sure it'll look great painted as well!

Michelle Morgan-Gillen says

Great Job! I love it!

Jenna Sue says

We have standard 8 foot ceilings but I wouldn't let height stop you! The good thing about planks is that they cover whatever issues you have going on so you can go right over the popcorn. If you are super concerned about the height, you can just get thin plywood boards ripped down into strips, which will still look great and it's definitely cheaper. Good luck!

Daniella says

Hi! The tongue and groove looks great!!! How tall are your ceilings? Our great room has popcorn ceilings and they're awful!! I have been thinking about finding something like a tongue groove to cover them but I'm afraid my ceilings are too low…? They are 7ft 3 inches! (it's a 1950's ranch). I've thought about scraping…but haven't had them tested for asbestos….I've thought about beadboard like you mentioned above…but I'm like you and love the look of tongue and groove the most! I've even thought about trying to have the ceiling removed but have no idea how much that might cost or if it's structurally possible, it's a pretty big area….just ANYTHING but popcorn! 🙂

DianeTaylor says

Hi Jenna – I have been following your blog for a long time but I think this is my first time to comment! My husband and I did this to our master bedroom ceiling and like you, it took us awhile to get into our groove. But oh I love the end result too. This looks amazing – ours was cedar plank and we had all kinds of issues with warped boards too. This reno is so cool – I envy you being able to design something that you truly love and make it happen!!!

Can't wait to see more….thanks for sharing this journey with us.

~Diane~

Jenni Ahokas says

Looking good! Using tongue and groove wood planks in very common here in Finland! As we live in a log house we have all our ceilings made using those pine planks, and I love them! When we bought this house, I painted all the ceilings white and it really made the difference. So good choice to paint 🙂 Looking forward seeing your walls, are you going to paint them? We used white stain, and I´m pleased how it turned out!

Enjoy the process itself and the huge progress you´ve made so far!

Sonya says

This is going to look so great! I commented on your YouTube house tour video that I can't wait to see the finished project but truly, this place is going to be gorgeous. Eagerly awaiting the finished product – as I'm sure you are too!

Deb says

Wow! Looks gorgeous and you guys have incredible energy!

Brad says

That was fun…except the attic part..icky.