Whew… if you’ve been following along in my Instagram stories, you know that Phase 1 of this closet makeover was a doozy! Let’s start with how it looked last week…

Before going any further, make sure you’re caught up with the Design Plans so you can follow along!

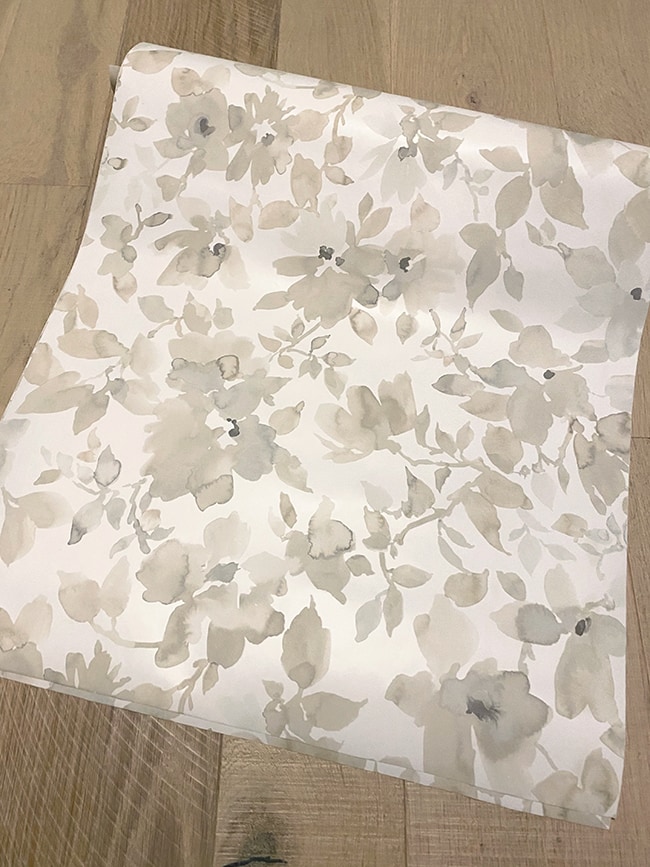

The first step of this makeover was adding wallpaper to the ceiling (much easier to do before the cabinets/trim are installed). If you recall from the Design Plan post I was leaning towards this wallpaper and ended up purchasing it, but was later notified that it was on backorder, so I went with my second choice…

I can’t tell you how many times I’ve had to go with Plan B (or C, or D…) and it ended up working out even better than Plan A. When projects don’t go as planned, there’s always a silver lining! This paper was a better choice because it’s peel and stick (easier to install on a ceiling), the color was a perfect match to our trim, and I couldn’t be happier with the way it turned out.

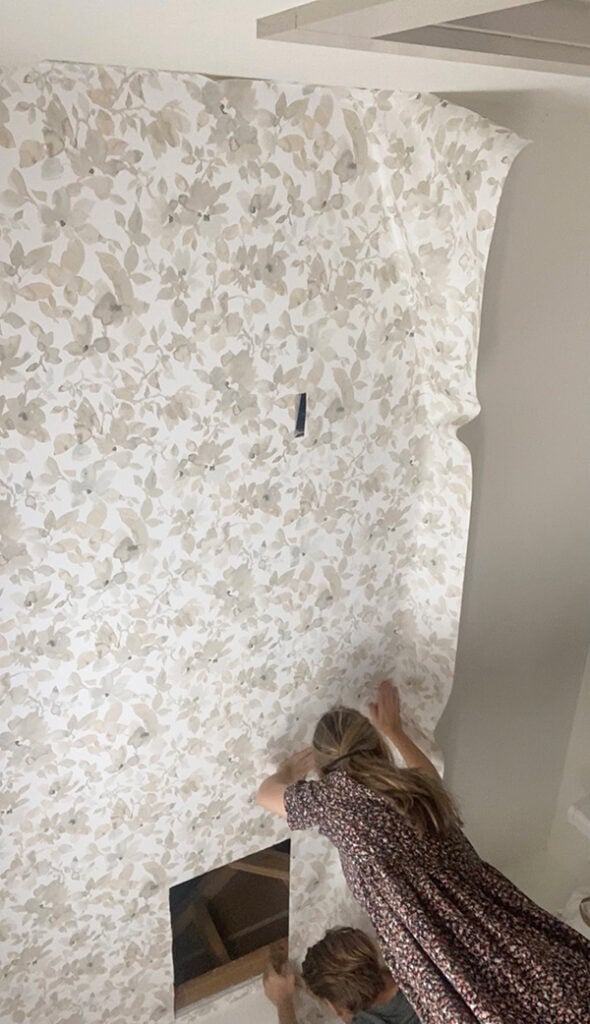

I won’t go too much into detail on the install (you can watch a timelapse of it in my stories) but basically, you want to line up the edge all the way down first, then smooth out side to side. This was my first attempt at wallpapering a ceiling, and it’s definitely more challenging with gravity working against you…

I’d highly recommend two people for this! Fortunately, our closet is small so it only took a few hours and no sore neck the next day.

We had a few obstacles to work around (the AC vent, ceiling light and attic access):

Not a big deal—the paper cuts like butter with a sharp utility knife.

We were so close to only needing three rows… but after the crown molding is installed, the wallpaper would have ended up about 1/8″ short. Fortunately, we had enough wallpaper to cut a section to fill in the gap.

This attic access is another situation we have to address later, since the crown will stick out slightly past the opening. My solution is to wallpaper over a thin piece of hardboard and attach that to the ceiling with heavy duty velcro strips.

We can’t do this until after the crown is installed though, so that will have to happen in Phase 2 (to be continued!) For now, just ignore the funky cut edges and know that it will all be hidden the behind cabinet trim.

See how perfect it is with the trim? Almost like it was color matched…

Alright, now let’s get to the real stuff. Time to clear out the closet and start building these wardrobes! If you recall from the Design Plans post, we are installing five Ikea Pax wardrobes in various sizes (three on the left, two on the right).

Ah, if only this whole project could be as simple as assembling Ikea furniture. Before getting the wardrobes in place, we had to build a platform for them to sit on, so first we had to remove the baseboards.

A platform will allow us to add tall baseboards to match up with the rest of the room, and give them a custom built-in look. The frame is built with 2×4’s, and is pretty much the same process we did for our Sektion cabinets in the playroom (more details in this post):

We built the frame *slightly* narrower than the depth of the Ikea wardrobes, to account for any unevenness in the wall (you don’t want the frame to stick out past the wardrobes and leave a big gap at the baseboard!)

Cross pieces were added to support the edges of each cabinet box, but the Pax wardrobes also have leveling feet at the bottom so we added additional 2×4’s on either side for those to sit on.

Those were attached with pocket screws, and 2×4 blocks underneath for added support.

Here’s the finished left side!

The process was pretty much the same for the smaller standalone boxes on the right side. Each 2×4 gets attached to each other and the walls (no need to drill into the floor).

Side note: see that little magnetic stud finder on the wall? It’s one of our favorite new tools—much more reliable than the battery powered type IMO. It grabs onto the drywall nails attached to the studs so there’s no guesswork.

All platforms done!

The last step is making sure the frames are level to the floor, and using shims where needed (we used these plastic shims which break off cleanly).

Now comes the real test… let’s see how they fit! Turns out we didn’t need to use the leveling feet to adjust since our bases were already level.

It helped that we weren’t trying to make the frames *exactly* the same size as the wardrobes. Walls are unpredictable and throw everything off (ahem, this is foreshadowing for what’s to come…)

Watching these go up was the most exciting part of our entire weekend.

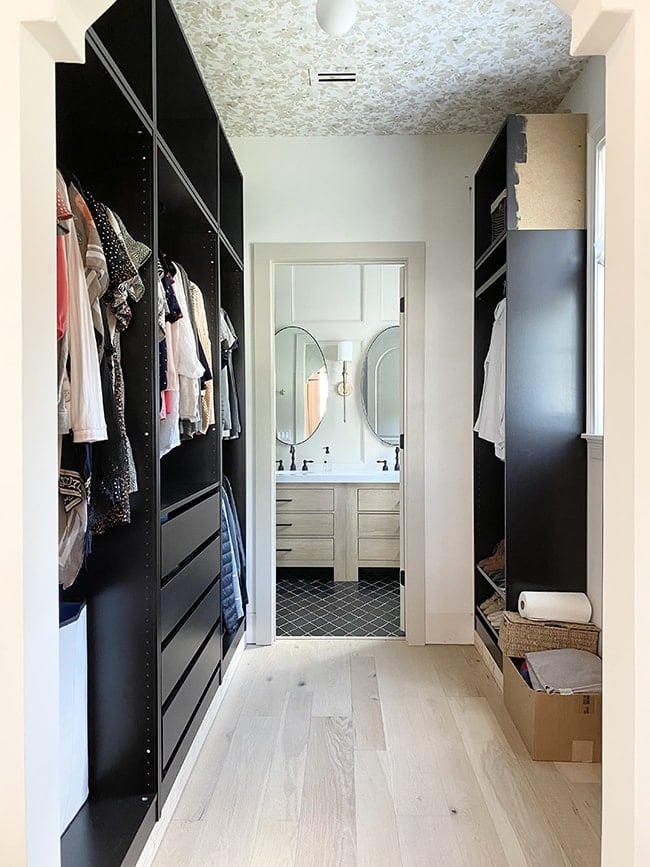

I know things will change once the doors are on, but the closet actually felt more spacious after the wallpaper and wardrobes went in. They draw your eye up and make the room feel so much taller, and the black boxes seem to give the walls more depth. I’m hopeful this space won’t feel too crowded when it’s all done.

The next day, we started by attaching the wardrobes to each other with the bolts provided by Ikea (make sure to line them up flush and clamp together first!)

We used three fasteners along the front on each side of the center wardrobe:

Next, we attached each cabinet to the back wall using the provided brackets. Because the bracket locations didn’t hit studs, we first used self-drilling drywall anchors:

Black caps clip onto the bracket so they aren’t too noticeable—these will also be hidden behind clothing rods (I’ll be filling all the unused holes with black caps as well!)

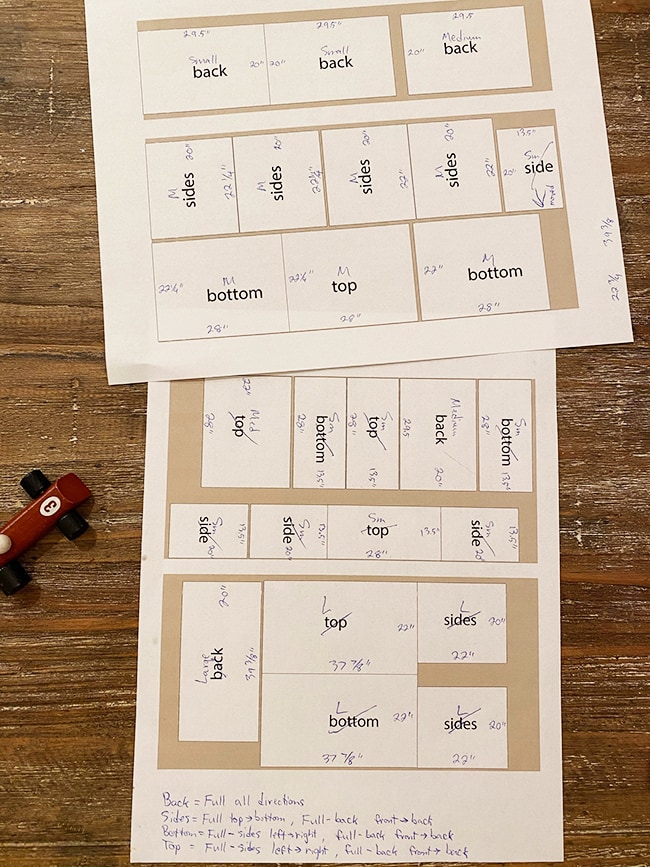

With the wardrobe boxes secure, it was time to move onto the next challenge—building the upper wardrobe boxes. This took a lot of careful planning, starting with mocking up each piece and laying it out in Illustrator to determine how much material was needed.

We ended up needing three sheets of 4×8′ MDF for all five cabinets, plus a half sheet of 1/2″ plywood we already had to use for three of the back pieces. We opted for MDF instead of cabinet grade plywood because it was half the cost, it cuts super smoothly with no splintering, and these would be rarely used/hidden behind doors so splurging really wasn’t necessary.

It took a while to arrange/rearrange all the cuts in order to maximize each sheet, and also calculate the dimensions for each one (since we were working with three different wardrobe sizes and two different material widths), but eventually, we had our plan and got to cutting.

Using the table saw was fastest, so we did that for almost all of the cuts (the full size MDF sheets are super heavy—you’ll want two people for this!) There was only one cut that was too wide to fit onto the table saw, so a circle saw was used for that.

Each piece was labeled and organized as we went, and two hours later, all 25 sides were cut and ready.

Time for assembly! Pocket holes are the way to go here and I’m a big fan of our Kreg Jig K5 system. We used the 1 1/4″ screws in the kit (coarse threads are better for MDF) and drilled two holes per side on the shorter boxes, three for the large boxes.

Each box has five sides:

Then it was time to assemble! After adding a bead of wood glue on the edges, we used our extra long bar clamps to hold everything flush and in place while the screws were inserted.

Then flipped it over to do the same for the other side.

Finally, the box was flipped on its front and the back piece attached (also with pocket screws).

Once all five boxes were made, it was time for paint. Cut edges of MDF are pretty rough, so I first sanded them down for a smoother finish.

I used Valspar Cracked Pepper in semi-gloss because it was what I had on hand, and I just needed them to be black. They’ll be hidden behind doors when closed (only seen by us when open, and rarely opened) so the color really didn’t matter too much, as long as it was black.

I haven’t bought the paint for the doors yet (leaning towards SW Tricorn Black) and I can always go over the boxes later if needed, but figured it was easier to paint them all now before they were installed. MDF and raw plywood soak up paint like a sponge, so it took just one quick coat for each (I only had to paint the inside and the face).

Moment of truth… time to get it in place!

Relief! It lined up almost perfectly. There was a slight overhang on the left side, but that will be hidden behind doors so it’s perfectly fine.

Sadly, that is where our luck ended. Upon hoisting the second cabinet into place, we realized it was a good 1/4″ too wide.

Then we checked the third cabinet—it was 1/8″ too wide.

Fortunately we were spared with the biggest cabinet, that was the right size (good thing, cause I was barely able to hoist this beast up over my head the first time)…

Before carrying the last one inside, we compared the wardrobe size to the cabinet sizes and realized they were almost all too wide—ugh. In our over-confident rush to get these finished, we failed to double check each measurement after cutting before assembling the boxes. Total rookie mistake.

We learned our lesson by spending the rest of the afternoon redoing our work—taking apart, cutting, re-drilling and reattaching three of the boxes.

Finally, we brought the new and improved boxes back inside and wiggled them in place. It all seemed okay until…

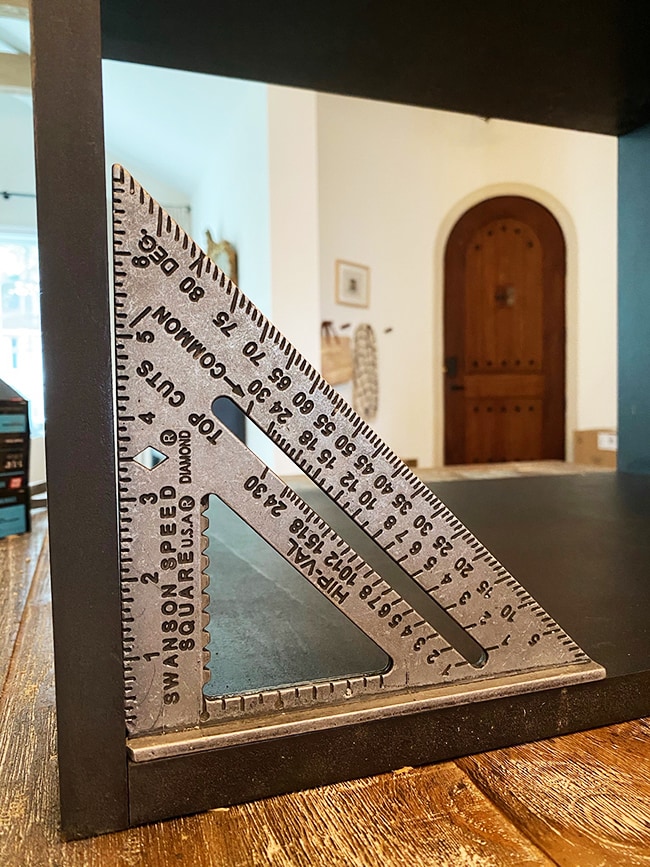

See that crooked gap on top? This cabinet was definitely not square. Down it came, disassembled once more, and reassembled with a square. Honestly I can’t believe how many mistakes we made with this project. There are so many moving parts, it’s easy to skip over the most basic steps I guess. Especially when you’re racing to get it done before your baby wakes up, ha.

Once we squared up the cabinet and reattached the back, we were able to line everything up pretty well. It still wasn’t perfect… because we made yet another mistake of trying to build boxes to the *exact* width/depth of the Ikea wardrobes, which didn’t account for any imperfections in the wall behind it. On the far right cabinet, one edge was hitting the back of an uneven spot in the wall, preventing it from sitting flush to the wardrobe. If we would have shaved just 1/2″ off the depth of these boxes, we’d have enough wiggle room to position them perfectly without worrying about making them flush against an (uneven) wall, too. This was the approach we used for the platforms—we just didn’t apply it to the upper boxes as well. Live and learn.

To attach the upper boxes to the wall, we made an “L” bracket with two 2×4’s, screwed the top into a stud in the wall, and the bottom to the cabinet (learned this tip from Chris Loves Julia). Finally, something we didn’t screw up, ha!

Just one L bracket per box is enough to keep them secure. We also screwed them into the top of the wardrobes which made them shift somehow and left us with a small gap between each cabinet. I swear, these boxes are so sensitive.

One thing I wasn’t loving was the noticeable rough texture of the painted MDF edges. Even though the boxes will be hidden behind doors, the finish was bothering me so I decided to investigate. Apparently the way to get around this issue is to either use an oil-based primer first (since MDF absorbs water-based paint and raises the grain) or use a good wood putty first. It was too late for primer and wood putty would have been a long, messy affair so I just tried sanding it down…

You can see the huge difference between the sanded edge on the right—it made it completely smooth. I figured a second coat of paint might raise the grain again and it did a little, but certainly not as bad as before. This I can live with!

Again, the goal was just to have black wardrobes/cabinet boxes that will blend in behind the closed doors. Not trying to match the black/brown Ikea finish, I don’t mind if that’s a little different since we’re the only one who will see it. If does bother me later, I can always touch up the edges with the black paint we end up using on the doors/trim so at least those will all match perfectly.

After all the ups and downs of this multi-day saga, Phase 1 is complete. We have functioning wardrobes!

This staged shot lasted all of five minutes before we shoved all of our belongings back in. We are still missing some shelves and things to organize them, but walking into this space makes me smile (it feels SO tall! And dark, and handsome).

Of course, you still have to look past all the gaps, lack of trim and finish panels, and missing doors and drawer fronts. As much work as Phase 1 was, I’m afraid Phase 2 will be a significantly larger operation. This is where everything will have to be precise—down to the 1/32″—and there’s no hiding any mistakes. It’s about to get real complicated.

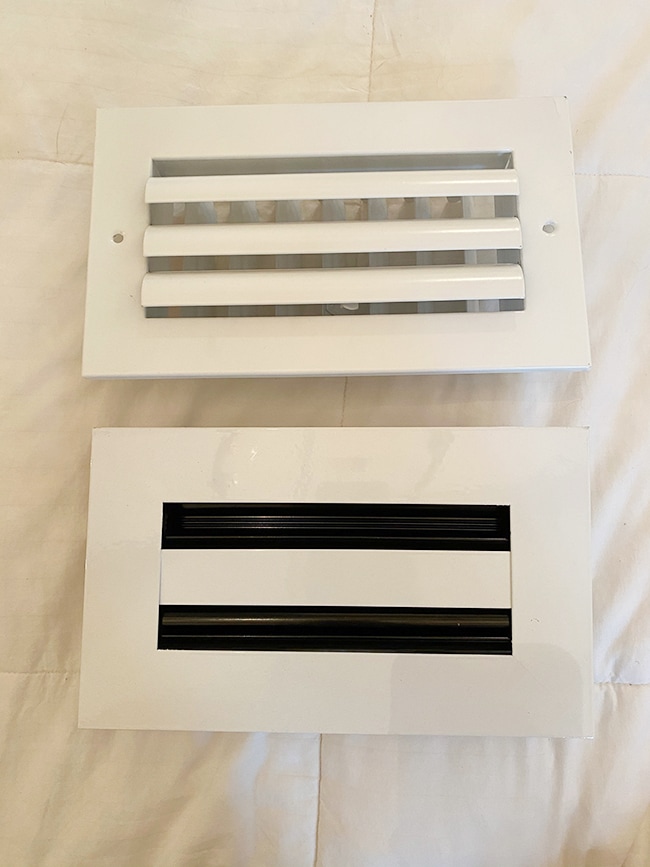

Did you notice something new on the ceiling?? Remember the old vent that was there before? Well there’s a new grill in town…

I found this minimal style vent cover on Amazon… much cleaner than the builder grade, right?

I was able to wallpaper right onto the flat front, so now it blends in much better than a bulky white register that would have stood out like a sore thumb on a focal wall.

And that concludes the end of Phase 1. Phase 2 will consist of the following:

- Adding 2×4 blocking along the top and sides for filler pieces

- Cutting, painting and attaching filler pieces, side panels, baseboard and window trim

- Cutting, painting and attaching decorative crown & baseboard molding

- Building a vanity desk with a custom accessory drawer

- Adding additional trim and mirror glass to doors

- Painting and installing doors & drawer fronts

- Finishing attic access panel, installing light and hardware

Whew… that’s quite the list! Maybe this will have to be split into two more phases. Painting will take the longest, by far (we’re spraying them all and that is quite a process) so I’m not sure when the next update will be. We’re waiting on the doors to arrive to test fit before we cut any of the filler pieces, which should happen by the end of the month.

In the meantime, I’m planning an easy/fun DIY to do this weekend that I can’t mess up. I need a morale boost over here after last weekend, hah. Onward and upward! Let’s see what next week brings…

Emily says

Congrats it looks great so far!

What color was the ceiling in your bedroom and closet before the wallpaper? Love the creativity. New favorite account!

Jenna Sue says

Thank you Emily! All of the walls/ceilings in our home are SW Alabaster.

Lisa says

Love the progress already and thanks for sharing the struggles of DIY life. I’m curious if you wasted a lot of wallpaper getting the wallpaper pattern to match up. It looks like a fairly large pattern repeat. Trying to figure out how to account for this when determining how many rolls to order.

Jenna Sue says

Thanks Lisa! Yes, we were less than a foot away from having the pattern line up so we had a lot of waste! Almost half of each roll. Good thing it wasn’t expensive wallpaper 😛

Christina says

I am so sorry for all the mistakes, but welcome to my world with EVERYSINGLEPROJECTEVER! I really, really hope that people aren’t giving you crud. You are a DIY business and we get to learn from you. So, with that said, aside from knowing well how frustrated you felt during and how your confidence is a bit shaken now, I am grateful for the mistakes and your learning curve b/c it directly benefits me. That sounds so selfish which I hate. (I am trying to rewrite that unsuccessfully….) I am not glad you made mistakes, but I am benefiting from your step-by-step telling/redoing of it all, so in that, I thank you for not hiding the mistakes. Seriously. Many of us are benefitting so please remember the good coming out of the bad…at your expense, true…but much good coming from the tell-all. Peace. Relax. I’d deliver a bottle of vino if I lived nearby! Cannot wait for the rest of it. Please keep on keeping it real and keeping us informed b/c it truly does help.

Jenna Sue says

I totally get it Christina, and didn’t realize how many people felt the same way! Thank you for letting me know. I will definitely make more of an effort to share each mistake from now on, since that is the best way for all of us to learn 🙂

Kathryn says

You are Lucas have done a great job. And no need to feel bummed about any mistakes. Mistakes are great teachers. Yes they are labor intensive but look how beautiful these cabinets are. And any cabinets going forward will be so much easier. Kudos to you…you two are a great team. The wardrobe closet is awesome!!!!

Jenna Sue says

Thank you so much Kathryn! That means a lot <3

Michele M. says

WOW!!! What a huge phase 1!!! Looking great over there.

I absolutely love love loooovvvveeee that wallpaper. Never thought of papering a ceiling. You are always thinking outside the box. That’s why I love your blog – such innovation.

BTW- your fella looks so cute with his dude mini ponytail. ♥ What a hard working guy.

and that cute little helper’s little hands. She’s growing up so fast.

Can’t wait to see phase 2 – you two never fail to amaze me.

Jenna Sue says

You are too kind Michele! I’m quite the lucky lady with this patient guy and our little DIY helper! 😉

Jamie says

What a great closet you guys have designed and are building. Your attention to detail (and sharing with us all) is amazing! I appreciate your honesty in all your work. From the design phase, though the building details, to the overall cost. You guys are truly gifted and such an inspiration to us all. Thank You for all that you do and allowing us to learn so much!

The closet looks great!

Jenna Sue says

Thank you so much Jamie, I am so glad you are enjoying the progresso so far!

Jenn says

What size Pax boxes did you use? We are in the process of Pax-ing all of our walk in closets in our house (we have four total, insert tired face). We used the taller 92″ boxes. It looks like you have the 79″ here but then added the homemade boxes on top. Just curious about the planning and why you chose to do it this way instead of going with the taller Pax option from the getgo and using a shelf to create the same effect up top? Regardless, looks great! Making me excited to get ours finished.

Jenna Sue says

Hi Jenn! They are the 79″ boxes and I chose that size so we could maximize the height with additional closed cabinet storage above. The 92″ boxes would have left us with a 16.5″ gap, which is too small for a cabinet plus trim/crown. With the 79″, there won’t be any wasted vertical space 🙂

Sindy says

JennaSue! I love your DIY adventures and how you always show the good, bad, and ugly. It gives me hope. When it isn’t right, you just do what it takes to get it right and don’t settle for “it’s close enough.” The closet looks awesome! On a different note, I noticed there were no ads in this post. In the past I have not been able to view all of your post because the constant ads kept kicking me back to the first photo. Try as I did I wasn’t able to get past a certain point. So! It was such a pleasure to be able to read the entire post and view all the photos!

Jenna Sue says

Thank you Sindy! I’m not sure what’s going on with the ads, the settings haven’t changed! They should never be changing your spot on the page–if you find they do that again, please let me know which post and I will have it fixed asap! <3

Lisa Jones says

Love the progress already and thanks for sharing the struggles of DIY life. I’m curious if you wasted a lot of wallpaper getting the wallpaper pattern to match up. It looks like a fairly large pattern repeat. Trying to figure out how to account for this when determining how many rolls to order.

Gina says

Great job and thank you for such a detailed tutorial!! So helpful to a beginner “diy”er like me. ?

Jenna Sue says

Thanks Gina, I’m so glad it’s helpful! <3

patricia says

Wow! What a mountain you climbed! But honestly, it really does help your readers to see you make mistakes and then course correct. That way we won’t be so frustrated when our projects don’t go perfectly the first time. Mistakes get made, but you picked yourself back up and redid it.

That will make the final project so much sweeter.

Jenna Sue says

True! I knew it wouldn’t be smooth sailing so I can’t say I’m surprised. I am hoping Phase 2 will be easier than expected though ;P

Jennifer says

You even pattern-matched the wallpaper on the grill! I am impressed. You’re right, even with half-painted boxes and no filler strips, it’s already looking great. I can’t wait to see the progress as you move forward.

Jenna Sue says

Thank you, Jennifer! I’m so glad you like the progress so far 🙂