If you love the classic look of grooved panels and want to save money by building your own cabinet doors, this tutorial is for you! Find out how simple and cost effective it is to DIY these plank style v-groove cabinet doors in minutes, using just a table saw.

When gathering inspiration for our laundry room renovation, I was particularly drawn to the classic and understated vertical groove cabinetry.

Shaker cabinet doors have been the standard for so long, and while they’ll always be in style, I wanted to try something different. Also referred to as plank, shiplap, beaded and v-groove style—these doors are not only an elegant alternative, but they’re also traditional and timeless.

Immediately the idea came to mind to carve the channels with a table saw. It seemed so simple, so we cut a test piece to find out. Lo and behold, it was just as easy as expected!

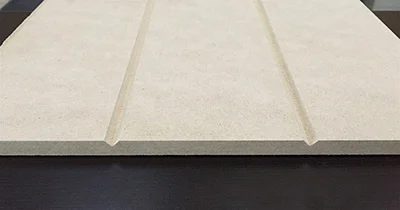

What is a v-groove?

A v-groove style refers to paneling featuring V-shaped grooves running parallel to each other. They are formed either by joining two boards together, or cutting channels into the material.

Traditionally, a router with a v-groove bit is used to cut these channels. However, you can also use a table saw to create a similar effect.

How to make v-groove cabinet doors

There are two ways to cut channels in cabinet doors:

- Router

- Table Saw

Custom cabinet makers use a router with a V-shaped bit to form a true V-groove. However, a table saw is an easier and beginner-friendly way to create straight channels that resemble this groove. From a distance, the difference really isn’t noticeable.

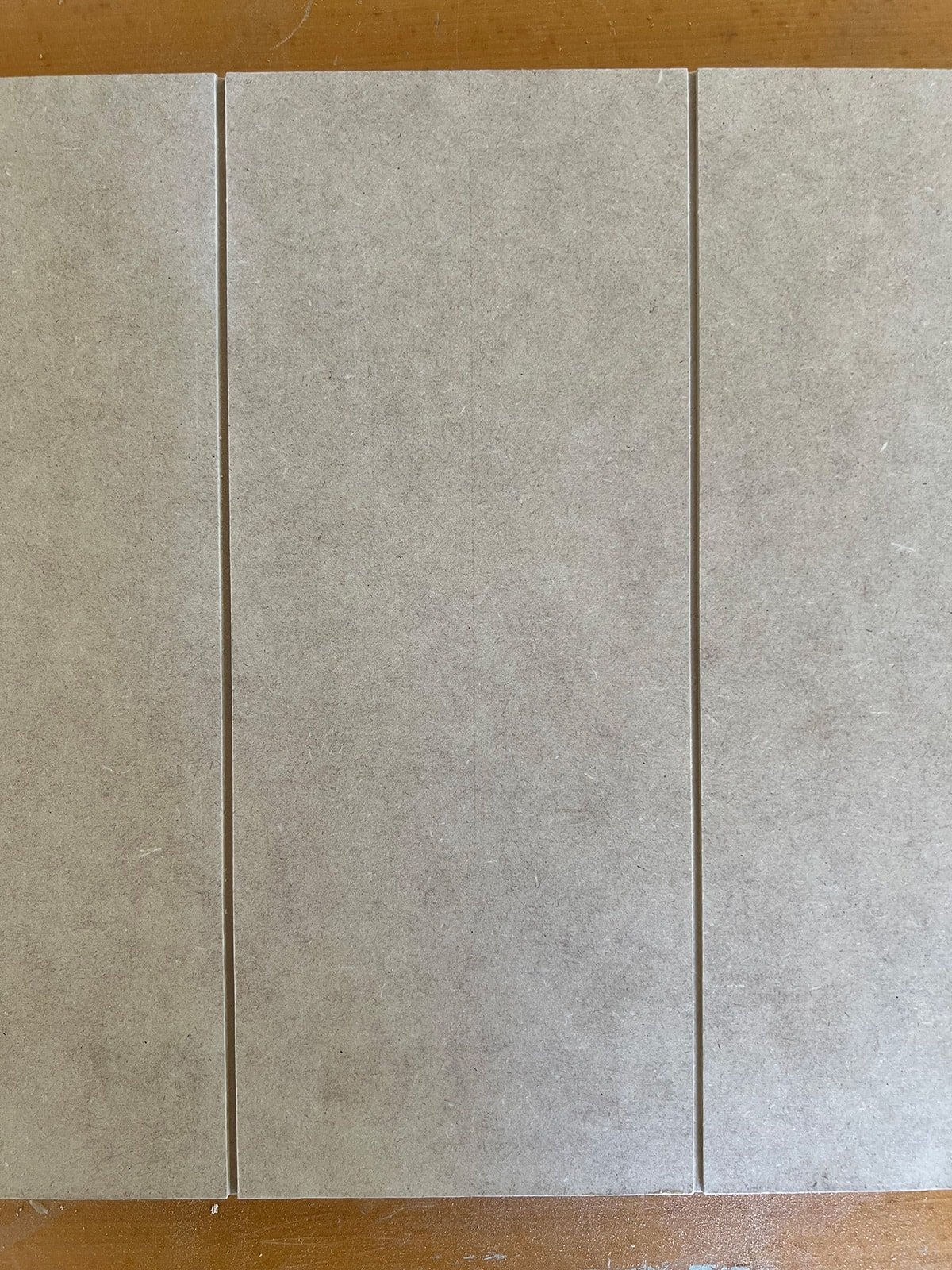

Door material

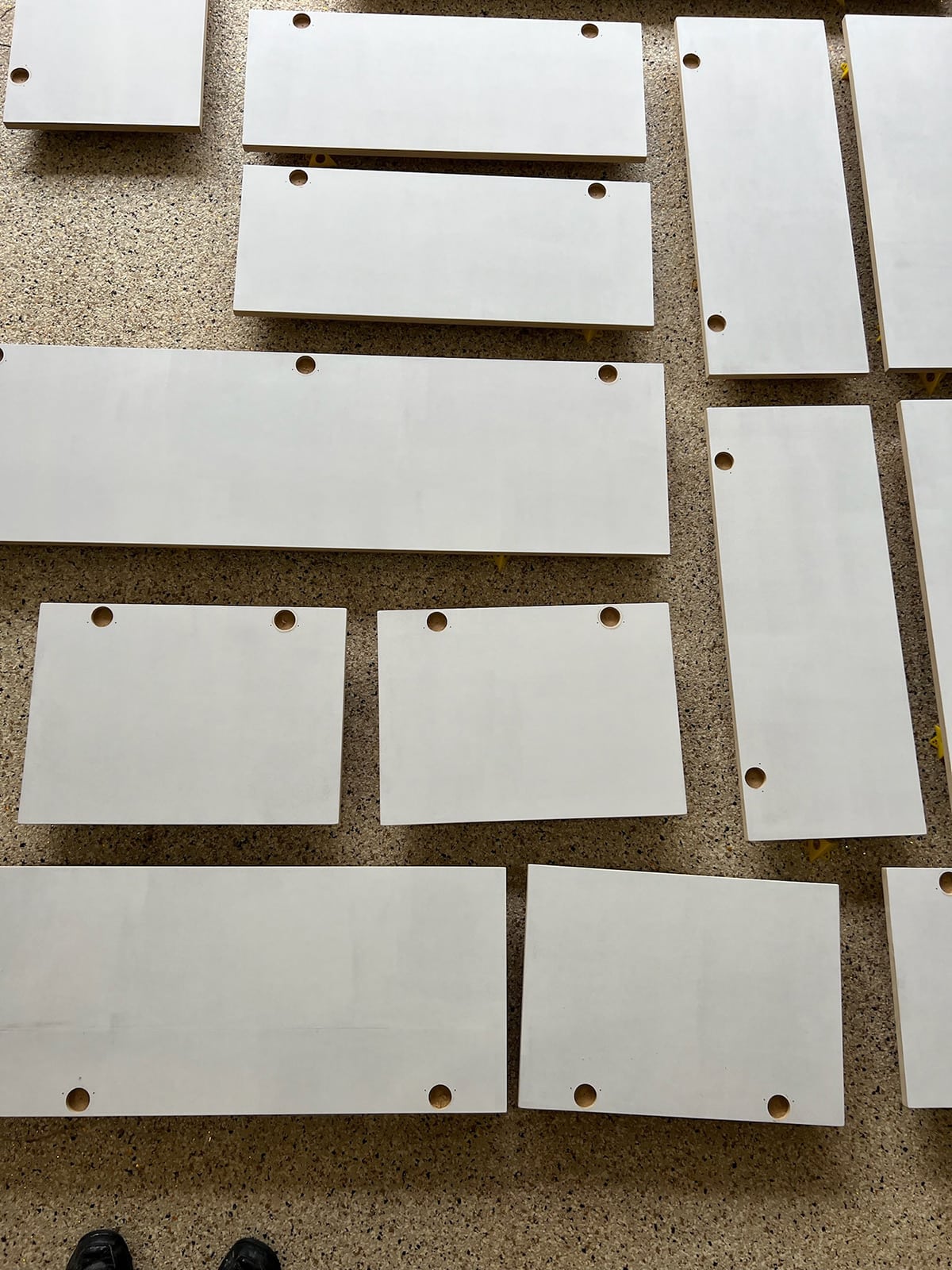

3/4″ MDF is ideal for this technique, as it’s cost effective, easy to cut, and designed for painting. We needed two 4×8′ MDF sheets to build 16 doors.

Raw cut edges of MDF are rough, so you’ll need to sand the edges smooth using 220 grit paper. Once the doors are cut and sanded, it’s time to make the grooves!

To determine line spacing, simply divide the width of each door by the number of grooves you’d like. We had four different door widths ranging from 12-20″, so our line spacing varied between 4″ and 4⅞”.

Set your saw gate to this measurement, and make the first cut for all of the doors with the same width. Then adjust the gate to the next line, and repeat the process.

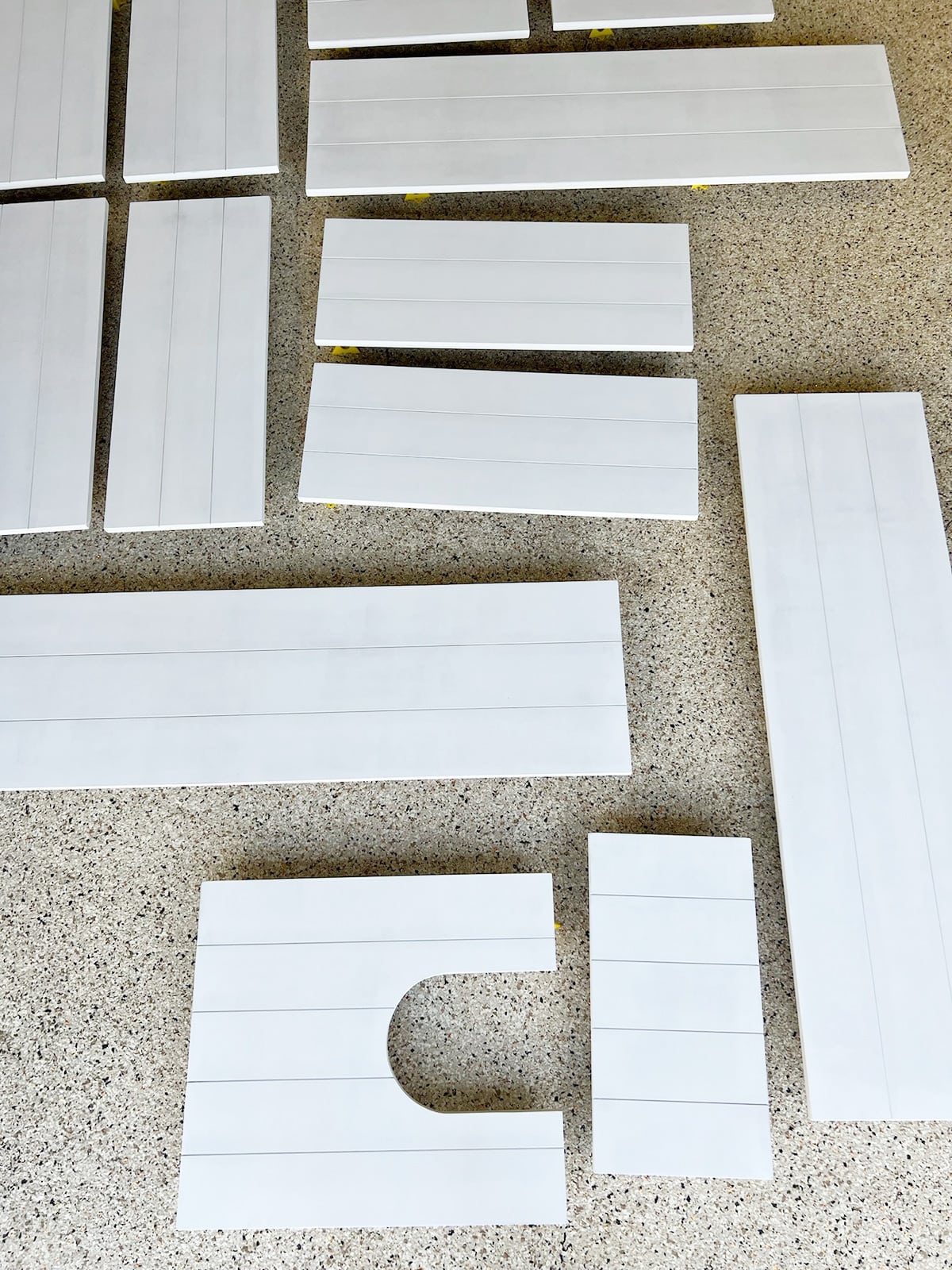

We set our saw depth to 3/16″, but I would recommend going deeper (~3/8″) for darker lines.

You can see the different line spacing below, but once they’re installed, it’s really not noticeable and doesn’t look off at all.

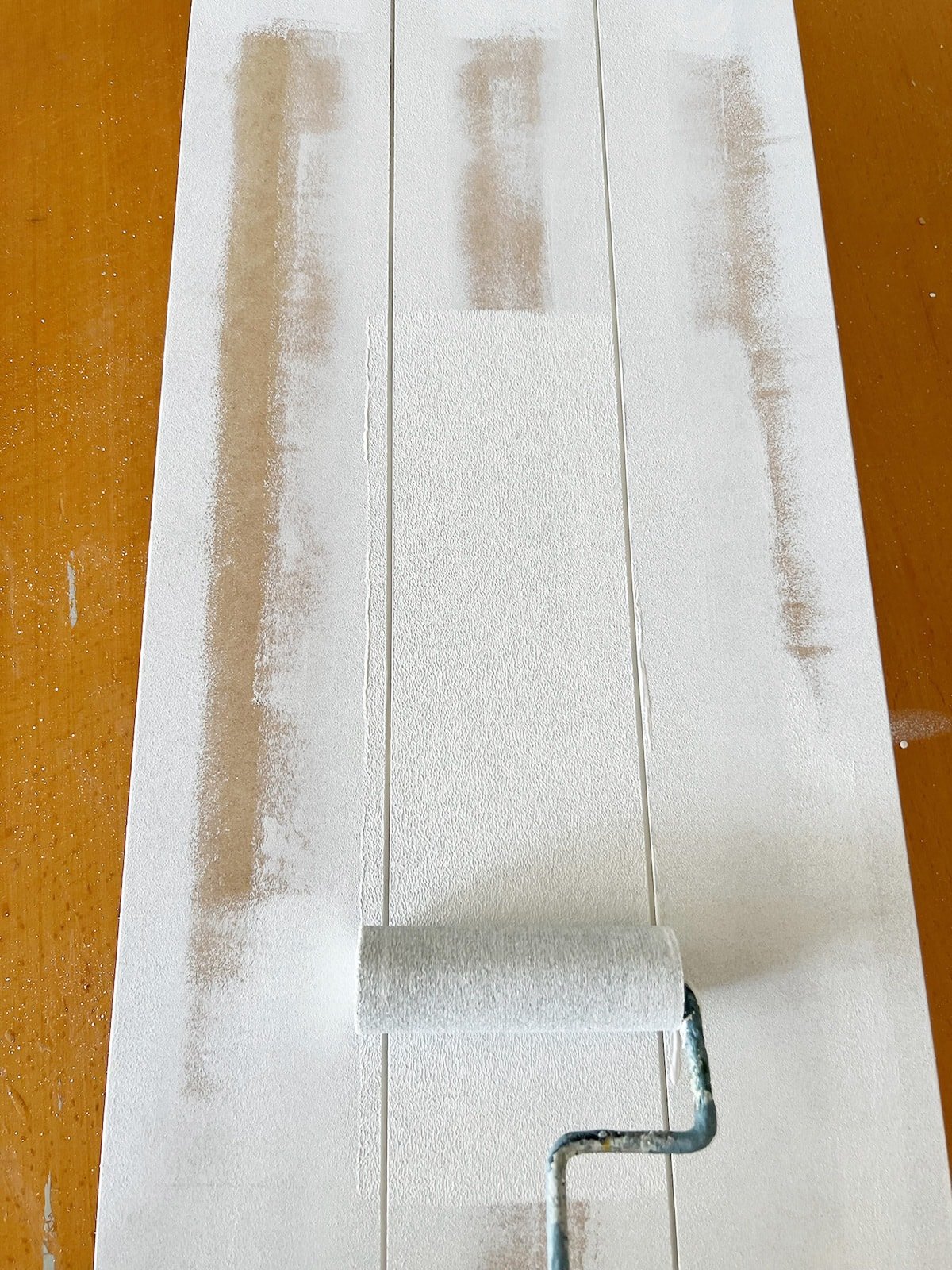

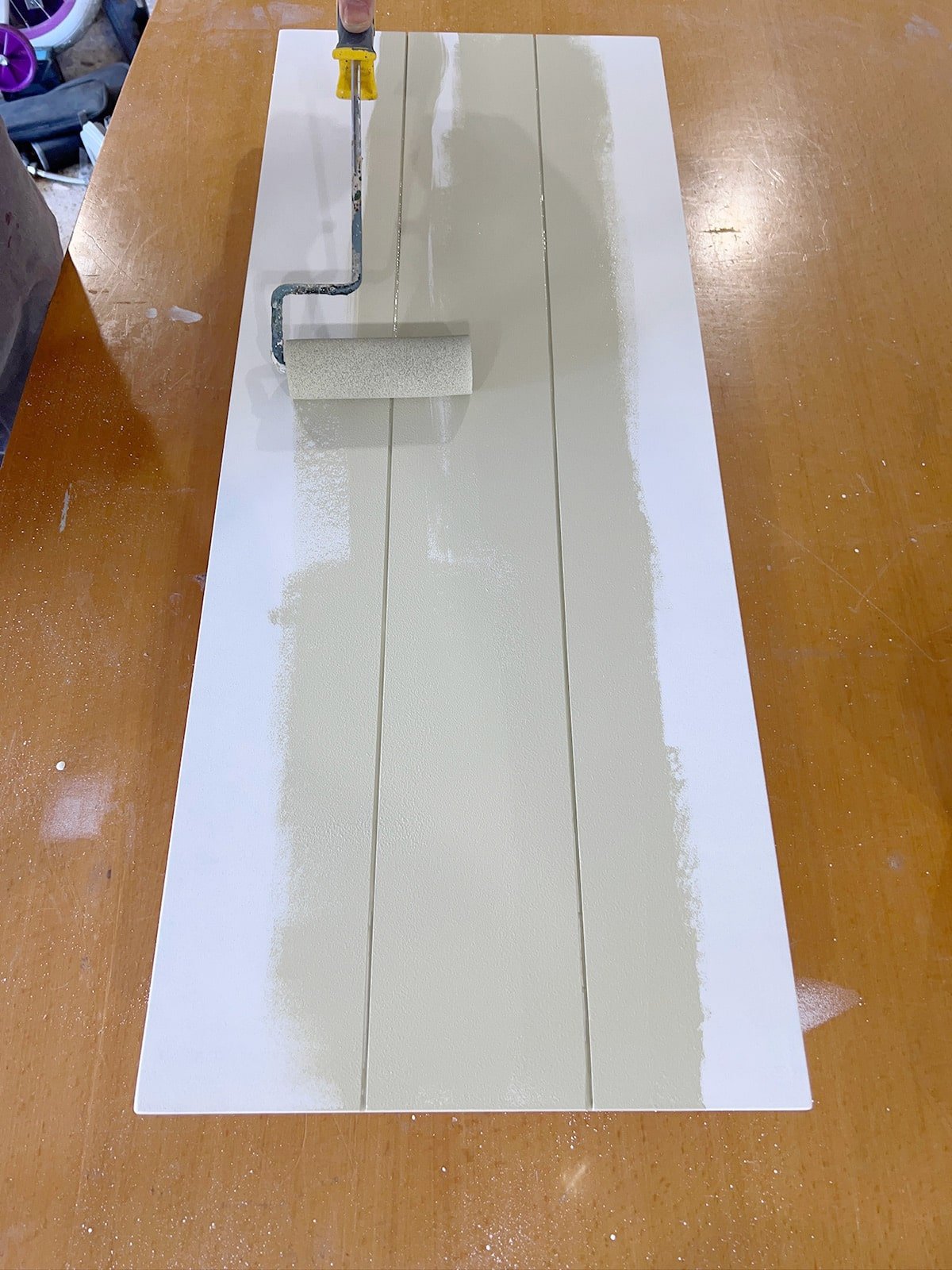

After all of the grooves have been cut, spray or roll on a good oil-based primer (we love Zinsser Cover Stain). Oil based is recommended because water based paints will react to the fibers in the MDF and make the texture rough (we learned this the hard way in our closet makeover).

You can find a detailed tutorial on how to paint cabinets, and the best paint rollers for cabinets.

Before painting, we needed to cut the hinge holes. This concealed hinge jig makes it much easier to cut precise holes every time.

We used these two-piece soft close hinges with a simple, clip in installation.

For the final step, we rolled on two coats of Sherwin Williams Urethane Enamel in Svelte Sage (satin finish).

Here’s how the cabinet boxes looked before the door installation:

The cabinet boxes were constructed using 3/4″ birch plywood, and birch edge banding along the face.

The cabinets are frameless with full overlay doors, but we created the illusion of inset doors by adding filler pieces and surrounding trim flush with the doors (you can read more about how we did this in our last kitchen remodel).

Helpful tips

After going through this process, here are the most important lessons to take note of:

1. Adjust your groove spacing to each individual door

For a seamless and cohesive look, you’ll want the groove spacing to match up with the reveal lines (the gap between the doors/filler). If your doors are different sizes, this means the line spacing will vary based on the door width.

This is one lesson we learned after designing our daughter’s bedroom built-ins. We used individual shiplap boards here so we weren’t able to adjust the spacing, but the uneven sections are distracting so I made sure to avoid that this time around.

2. The deeper the groove, the darker the line will be

Our grooves were cut 3/16″ deep, and I had incorrectly assumed that the grooves would be as dark as the reveals. After the doors were painted, however, the grooves appeared lighter and you can definitely tell them apart from the reveal lines.

If you prefer the groove lines to blend in with the reveal lines, try cutting them a bit deeper (~3/8″). Also, try to match your groove width to the reveal size (ours are around 3/16″ wide for both).

3. Make sure to keep the door pressed down firmly when cutting the channels

This was a mistake that wasn’t caught until after the door was painted. When cutting one of the grooves, Lucas lifted his hand so there wasn’t enough pressure on it, and we ended up with one 3-4″ section that wasn’t as deep as the rest. Fortunately, I was able to conceal it with a fine paint brush and custom green-black paint mix to make the shadow appear darker.

And that’s all there is to it! After a dozen custom built-in projects over the years, this one was probably the most straightforward with the best end result. These DIY doors couldn’t be easier or more cost-effective, and we’ll certainly be using this technique again.

Let me know your thoughts on this door style, and if you’d want to try it out!

Katelyn says

Hiii, can you give details on your litter box situation? I plan on having ours in the laundryroom too. But noticed yours is raised up a bit. Why did you make that decision? And is it hard cleaning it with it tucked in the back like that?

Jenna Sue says

We actually have a self cleaning litter box! It’s the Cat Genie. We only need to access the area periodically for maintenance, and the door is simply attached with magnets. Highly recommend.

Sue says

Love this laundry ♥️ how do you clean out the kitty litter, do you remove the door?

Jenna Sue says

Thank you! We have a self cleaning litter box so we don’t need to access it very often, but the entire door is held on by magnets and can easily remove.

Stacey says

Beautiful and well worth the wait. I would love a bit more detail on the filler/face frames to make the cabinet doors look inset. I went back to the link you shared but you do not share any details on this part of the install. Could you or Lucas share a bit more detail here? Thanks so much!

Mandy Allen says

I’m no woodworker but I still read these DIYs as they are so interesting, and there are good tips i.e. using oil based primer on MDF.

I did spot the section on your laundry cupboard but only because I was looking for it, likewise I had to really look around your daughter’s bedroom photo! I would never have noticed either if you hadn’t mentioned them. Shhhh! (but thanks!)

Well done on another beautiful room with excellent DIY (although quite honestly, you guys are more than DIYers these days.

Jenna Sue says

That means so much! Thanks Mandy ❤️

Juliana Wilfong says

You are so talented. Love these amazing cabinets. I have been brownsing around your website for about 45 minutes now. Fabulous content!

Jessica Barbosa says

Thank you so much for sharing!

Lori says

I love the restraint in the way you fabricated the grooves on these cabinets. Making it look effortless requires so much thinking, but you really achieved it with this project. All of those decisions add up to an internal logic that makes sense in the space and reflects the confidence of the design and execution.

BettyAnn says

Fabulous cabinets! We will be using this technique on the original kitchen cabinet doors of the 1947 summer cottage we recently bought.

Thank you so much